R&D

A company that leads new ideas and changes

Areas of Development

- R&D

- Areas of Development

- Development of Hydraulic System Monitoring & Failure Diagnosis Prediction Analysis Remote Diagnosis System

-

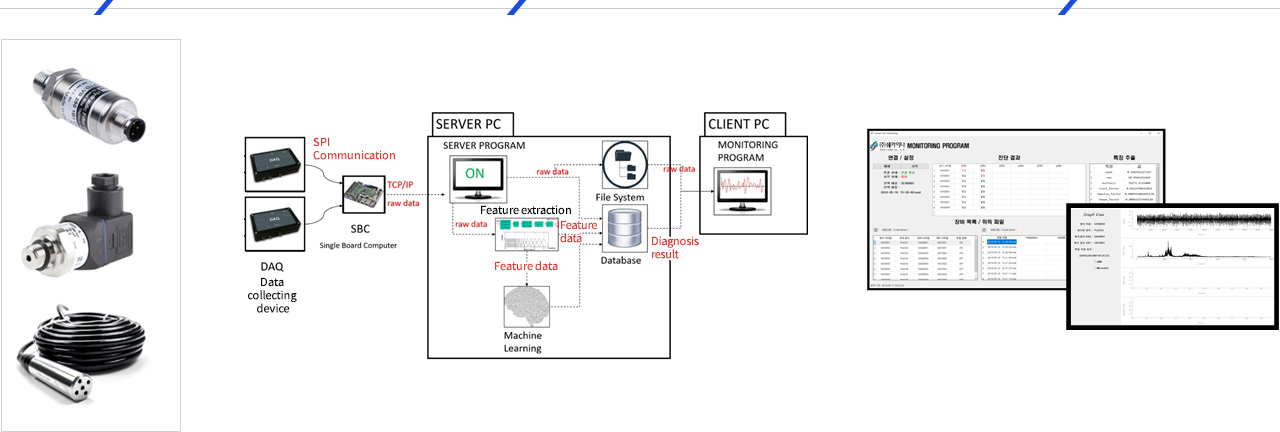

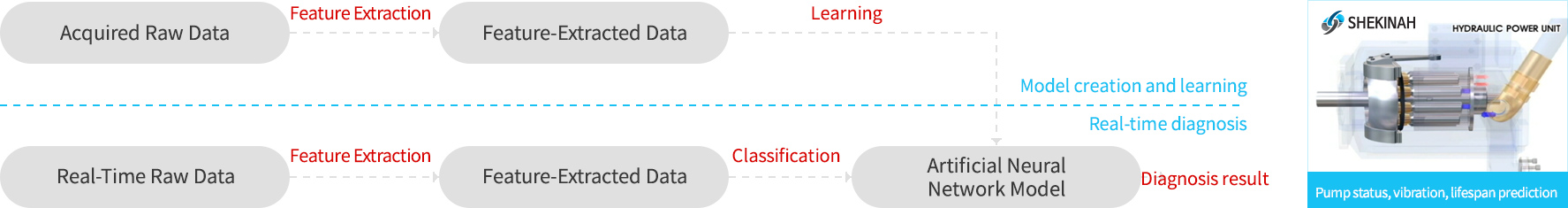

CBMDiagnoses faults and monitoring them in real-time by applying the CBM (Condition Based Maintenance) method.

CBM(Condition Based Maintenance) A status-based preservation method that aims to minimize the impact on facility operation, make the lifecycle of facility the most economical, and detect and predict abnormalities early by identifying the facility condition through a scientific method.

Temperature, pressure, flow rate, oil condition (pollution level), vibration

Systematically manages the data acquired from multiple sensors Quickly identifies the hydraulic system status through data acquired in real-time

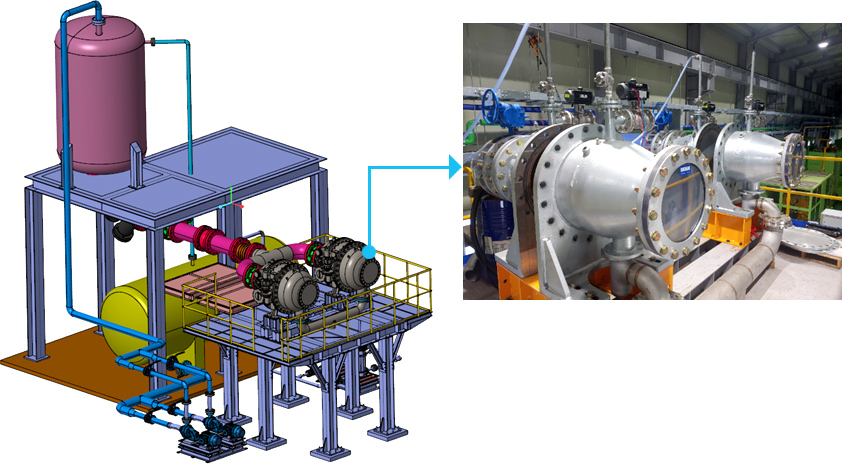

- Butterfly Valve Performance and Lifespan Testing Device

-

Installed a leak-check window to eliminate the inconvenience of disassembling and re-installing the pipe to check for leaks.

Combined and detached with a slide bracket method to shorten the time to loosen and tighten the bolts for a lifespan test.

Derived reliability factors through an accelerated life test, created an acceleration model through this, and developed a lifespan model that predicts lifespan under actual use conditions.

The monitoring and fault diagnosis system that Shekinah Co., Ltd. is currently developing provides reliable predictive information based on its experience of manufacturing numerous hydraulic systems in various industries and by using big data and IoT of commercially operating products. Through AI algorithms, it can analyze the data and predict in advance possible problems that may occur.

ENG

ENG