Business Area

A company that leads new ideas and changes

Turbine Lubrication Systems

- Business Area

- Maintenance & Spare parts

- Turbine Lubrication Systems

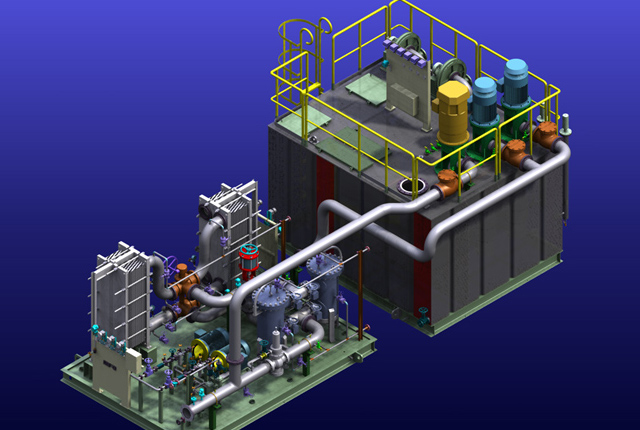

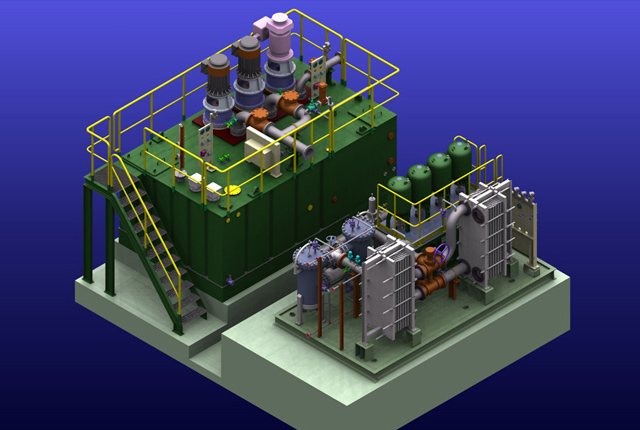

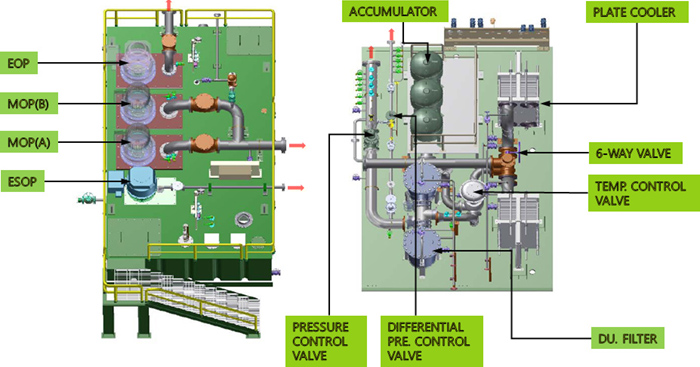

The Lube Oil System consists of Oil Reservoir Tank, 3 motor-drive pumps, Oil Cooler and Filter, Pressure Regulating Valve, Local Control Panel, and necessary piping and instruments.

Each lubricating device supplies lubricating oil to the bearings and other parts at an appropriate pressure and temperature when the turbine and generator shaft rotate, and it performs gamma, cooling, sealing (hydrogen), stress distribution, rust prevention, and cleaning.

- OIL TANK

- The oil tank is placed next to the turbine, and the instruments for oil system are installed on the Local Control Console. The oil pump, vapor extractor, and expansion cover are installed on the top of the tank, and most oil pipes are installed on the oil tank and the turbine front standard. The pressure inside the tank is maintained at a slight negative pressure by the Vapor Extractor.

- OIL PUPM

- There are two AC motor drive Main Oil Pump (MOP A/B) and Emergency Oil Pump (EOP), and the main lubricating pump lubricate all high pressure turbine generator when it is in normal operation. As the last protective device installed on the emergency oil pump (EOP), it runs by the direct current (DC) power supplied by the Battery Room installed in each power plant and can provide power continuously for about 2 hours depending on the power supply capability.

- JACKING OIL TANK

- When the generator rotor rotates, the Jacking Oil Pump acts as a rotor in a stationary state to prevent damage to the bearing bar bevel surface by the rotor's own weight.

ENG

ENG