Business Area

A company that leads new ideas and changes

One-stop Oil Management Service

- Business Area

- One-stop Oil Management Service

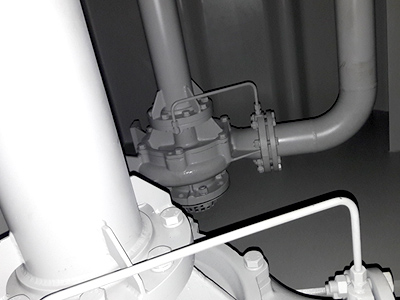

01. Oil tank cleaning work, hydraulic piping system flushing

-

EHC-HPU tank interior cleaning

-

Lube Oil tank interior cleaning

Using abundant experience and optimized equipment, our One-Stop Oil Management Service completely eliminates even varnish that is difficult to remove, perfectly solving the contamination inside the tank. In order to ensure the safety of workers as a top priority, Shekinah Co., Ltd. has state-of-the-art safety equipment that can monitor, survey, and communicate the working environment in real time.

02. Pollution cause analysis

The collected hydraulic filler element is thoroughly analyzed and disposed.

By analyzing the removed filters and the cleaned contaminants precisely, we analyze the contaminants such as varnish, carbon, iron, scale, moisture, etc. to find out the problems of equipment operation and present the optimal solution accordingly. During cleaning and flushing and before and after oil refining, we measure pollution (moisture, acid concentration, turbidity, particulates) as many times as necessary using the latest contamination meter we own.

03. Provides the optimal oil management solution (Oil Purifier Customizing)

We present the best oil purifier based on products of Pall, which has the world's best technology in oil filtration. By completely understanding the existing system and identifying the characteristics, we offer the best suggestions with various options according to the site situation and conditions. We can significantly minimize production loss and reduce facility failure rate due to oil pollution, and provide custom-made, optimal products that can guarantee operator's work convenience and safety.

-

01

VMU, IXU system –Removes varnish-

- ㆍRemoves concentrated and polymerized varnish precursor by a very fine offline filter.

- ㆍRemoves acid and metal soaps with ion exchange resin.

- ㆍCan design the number of filter housings from 1 to 4 depending on the capacity.

-

02

FAM system –Oil/water separator (removes water)-

- ㆍVacuum Dehydration Method

- ㆍSize design available according to flow rate 5ℓ~90ℓ /min

-

03

Control panel –Real-time display of operation, contamination, and moisture

ENG

ENG